Level switches and controllers are devices designed to measure and regulate the level of liquids or solids in tanks or containers. They ensure that optimal levels are maintained, preventing overflow or underflow situations, which could lead to damage. Level switches and controllers use various sensing technologies, such as floats, pressure sensors, ultrasonic sensors, capacitive sensors, radar, mechanical devices to measure liquid or solid media levels accurately. Among these, ultrasonic level sensors offer a reliable, non-contact method, particularly beneficial in harsh environments. In fact, an ultrasonic level sensor is a specialized type of ultrasonic sensor with a primary application for liquid level measurement. Controllers are equipped to receive input from the sensor(s) and provide output signals to control valves, pumps, or other devices to maintain a desired level.

Davis Controls supplies the following brands of Level Control solutions, offering a range of level controller devices and sensors to offer precise measurement and control of liquid and solid levels in various applications.

Explore our solutions by clicking on the brand below:

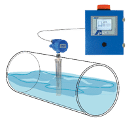

Magnetostrictive transmitter

This liquid level transmitter is based on the magnetostrictive measuring principle. The measurement process begins with a pulsing current through a wire made of magnetostrictive material. The magnet-fitted float sits upon the surface of the liquid being measured, and the liquid level can be calculated when the pulse reaches the float position. This is an extremely accurate process, recording results within ±1 mm. The APG Magnetostrictive Transmitter is easily calibrated and can be controlled in situ or remotely and is unaffected by temperature or corrosion.

Arjay manufactures a complete line of level controls and monitors for both liquid and solid applications. These solutions employ a unique Radio Frequency Capacitance circuitry to maximize accuracy and minimize maintenance.

The 2882-LS Probe Mounted Switch provides reliable level alarm and control of liquids and solids. As a liquid or solid rises or lowers around the probe, the capacitance field changes. This is monitored and used to control the two on-board relays.

Each relay includes full differential control to allow the relay to activate and de-activate between two distinct at user determined points on the probe. This can be used for pump and valve control between high and low level points. Adjustable time delay is standard to suppress spurious alarms from turbulence.

Hazardous Location Use

- 2880 Electrical Safety UL, CSA, or IEC 61010

- Housing UL/FM/CSA

- Class 1, Group B, C, D;

- Class II, Group E, F, G

- Probe CSA Class 1, Group C, D

The electronics for this model can also be mounted remotely from the probe. The probe becomes Intrinsically Safe when ordered with an IS Barrier installed in the 2852-LS control panel: CSA Div 1, Class 1, Groups A, B, C, D

The 4100-LEV provides continuous level monitoring of liquids and bulk solids. The 4100-LEV unique level system provides complete flexibility for monitoring one or more tanks in one complete package.

The 4100-LEV Sensing Probe monitors the capacitance field between the probe and it’s concentric shield or the straight metallic tank wall. As the level of product increases, the probe capacitance changes. This level signal is used to provide outputs, displays and relay control.

- No moving parts

- Remote electronics via standard twisted pair

- All set-up, calibration and diagnostics are accessed at the control panel

- All control wiring and interface is done at the control panel

- HF capacitance technology does not require routine cleaning

- Touch-screen interface for easy set-up and user interface

- Tank view display for ease of reading

- Trend display of hour, day or month increments

- Unique capacitance approach eliminates routine cleaning

- Control and interface panel mounts safely away from the process

The core of the submersible level probe is a piezoresistive measuring cell, which features high overload resistance and is particularly stable, reliable and temperature resistant. The level probes are manufactured entirely from stainless steel and are therefore resistant to a wide range of media. Maximum security during start-up is guaranteed by reverse polarity protection that protects the measuring device against damage.

Level probe for continuous level measurement in liquids:

- Measuring ranges: 250 mbar to 2.5 bar

- Medium temperature: 0 to 50°C

- Piezoresistive silicon sensor

- Accuracy: 0.3% MSP (linearity) (also available 0.2 % MSP)

- Excellent long-term stability

- High overload resistance

- Reverse-polarity protection

- Drinking water approval

- Suitable for indoor mounting

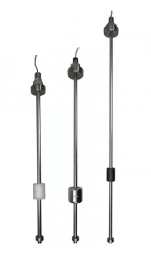

Point level float switches use reed switch technology that is simple, reliable and durable. They operate in an on/off state and are used to control an external device such as an alarm or an on/off switch. Certain point level float switches are offered with field-adjustable stem lengths. This provides an OEM with the advantage of needing only one model for their applications instead of several.

General applications for point level sensors include high-low level alarm triggers, overflow or spill prevention, and pump control. Multi-level float switches can be configured for specific applications.

A magnetic float travels up and down the stem between float stops actuating or de-actuating a dry contact reed switch encapsulated inside the stem. When the magnetic field comes in close proximity to the reed switch, the float switch contact closes.

Float Switch operation is determined in a dry condition (Empty Tank) with the installation fitting up and the float at rest against the lower float stop for vertical float switches. For horizontally mounted float switches, the float switch assembly can be rotated 180 degrees for normally open or normally closed operation.

General applications include measurement of liquid layers, such as oil/water, liquid material inventory, flow rate management, and in high temperature, high pressure and corrosive environments. Continuous float level sensors are best used with clean liquids but are not affected by turbulent conditions.

Point Level Measurement

Point Level Switches and detectors detect media at a predefined position depending on the installation position.

Level detectors are mainly installed as full or empty detectors in the upper or lower part of a silo or container. This prevents the silo or vessel from overfilling or running empty.

Bulk solids sensors differ from those for liquid sensors. For this reason, UWT offers a broad portfolio of different technologies such as rotary paddle switches, vibration level switches and capacitive sensors.

Continuous Level Measurement

Unlike point level sensors, which can only detect a media level at a predefined point, Continuous level sensors detect the exact level of a medium in real time.

There are different technologies for continuous level measurement such as capacitive and radar sensors as well as electromechanical plumb bob systems; all of which have advantages but also disadvantages depending on the application.

Contact Us

Contact Davis Controls today about our state-of-the-art products and experience our expert application advice and reliable service!

CONTACT US