Explore our solutions by clicking on the brand below:

EXPLOSION PROOF (Class 1 Div 1/Zone 1)

FLOW

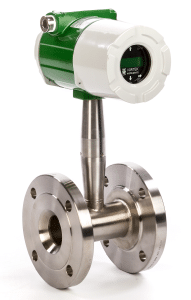

Pro-V® Inline Vortex Flow Meter (Model M24)

VorTek Instruments Pro-V® M24 Multivariable Vortex Flowmeter offers accurate and reliable flow metering in a multivariable design. The multivariable design incorporates a high-accuracy velocity sensor, a precision platinum RTD temperature sensor, and a solid-state pressure transducer. The M24 can deliver volumetric flow, mass flow, temperature, pressure, density, and energy (BTU) measurements from a single installed device. This drastically reduces complexity, equipment costs, and installation costs in comparison to installing multiple stand-alone instruments to arrive at the same process measurements.

The M24 includes a reduced bore option. The meter’s process connections match the line size but by using integrated reducing flanges, the meter body is reduced in diameter. This increases the fluid velocity through the meter. Increasing the velocity in this fashion extends the meter’s measuring range to capture lower flow rates that might otherwise be missed in a full line size meter. This reduced bore option also shares the same face-to-face dimension as a standard M24 meter for pressure classes up to ANSI 600

The M24 flowmeter offers an industry-leading variety of communication and power options. In addition to providing traditional communication methods such as analog output signals, the flowmeter also offers the latest and most advanced serial communication options such as BACnet®/IP and Modbus® TCP/IP. The M24 is the only vortex flowmeter on the market to provide Power over Ethernet (PoE) capabilities. Power over Ethernet functionality delivers power and data through a single ethernet cable. Both simplifying installation and reducing installation costs.

Series V4 Flotect® Vane Operated Flow Switch

Field Adjustable – Dependable Protection Against Flow Variation or Stopping in Pipelines for Fluids, Gases and Flowing Solids

The Series V4 Flotect® Vane Operated Flow Switch is rugged and reliable, ideal for automatically protecting equipment and pipeline systems against damage from reduction or loss of flow. Time tested in thousands of pipeline installations and processing plants around the world this Series is Weatherproof, designed to meet NEMA 4 and Explosion-proof. This series can be used in pipes 1-1/2˝ (38.10 mm) and up.

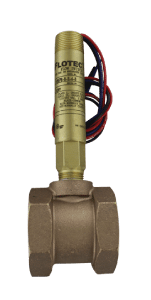

Series V6 Flotect® Mini-Size Flow Switches

Monitor Flow in 1/2″ to 2″ (12.70 to 50.80 mm) Pipe, Explosion-Proof, Compact

The Series V6 Flotect® Flow Switch is surprisingly compact, and specifically engineered to monitor liquid, gas, or air flows. Time tested in thousands of pipeline installations and processing plants around the world, this Series is Weatherproof, designed to meet NEMA 4 and Explosion-proof (listing included in specifications). Tees are available for installation in pipelines from 1/2″ to 2″ (12.70 to 50.80 mm). With bushings added the unit is easily adapted to 1/4″ and 3/8″ (6.35 and 9.53 mm) piping.

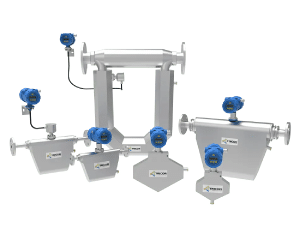

The TRICOR CLASSIC product line meets general industrial requirements with out-of-the-box ease of use. Lower cost and lower performance specs meet broader application needs. Typically used in paint, coating and dosing of non-corrosive fluid requiring 0.3% accuracy and low to zero maintenance

- Flushable TCE 8000 transmitters with an easy-to-use interface

- Optional custom-calibrated meters with high performance specifications

- No moving parts

- Simultaneously measuring of mass flow, density and temperature

- Calculation of volume flow as well as mass and volume total

- Flushable

The TRICOR CLASSIC Mass Flow Meters are available as compact versions with onsite display and as meters with remote display for wall or panel mount.

All versions are available as standard versions as well as Ex Certified for hazardous location (cCSAus). The meter provide the following features:

- A graphic display

- Menu driven control with soft keys for easy operation (also with manual)

- Magnet hall switches for Ex areas

- Two freely programmable 4-20 mA outputs

- One freely programmable frequency output

- One control input and one control output

- RS485 interface

RT-30EX – Hazardous Area Rated Flow Transmitter

The RT-30EX Flow Transmitter is a rugged display with certifications for use in Hazardous Areas. The weatherproof NEMA-4x/IP-65 enclosure features a digital display that offers a variety of screens, including Rate, Total, Grand Total, Status and more. Flow rate and total are easily programmed to the engineering units of choice in the field. The easy thread-in installation and quick setup procedure allow you to be up and running quickly. Transmitters can be mounted locally to the flow meter or remotely.

- Backlit LCD Display

- Rate and Totalization

- HART Communication (optional)

- Linearizer for additional accuracy

- Frequency and 4029 mA outputs

- 2 opto-isolated limit switches

- Ex Certifications: CSA (US and Canada)

LEVEL

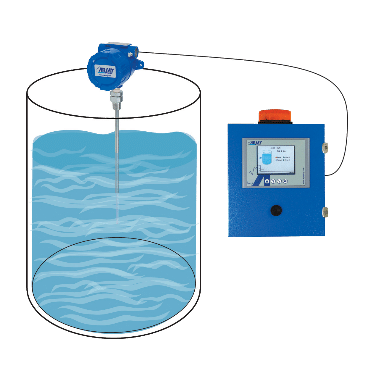

4100-CAP Capacitance Monitor

Continuous Capacitance/Dielectric Monitoring of Liquids and Solids

The 4100-CAP provides continuous capacitance/dielectric monitoring of liquids or solids. This unique system provides complete flexibility for monitoring solids and liquids for concentration, moisture content, blending and quality control.

The 4100-CAP Sensing Probe monitors the capacitance field around the probe within a shield, tank or pipe. As the dielectric characteristics of a fluid or solid change, the resulting capacitance change is monitored and configured into a usable signal for process control and recording. A display is available in user-configured engineering units.

Product dielectric changes in your application may not be strictly linear. Arjay has designed a 5-point calibration into the controller to enhance accuracy over an extended measurement range. This instrument is ideal for general monitoring and trending of process conditions.

The 2882-LS Probe Mounted Switch provides reliable level alarm and control of liquids and solids. As a liquid or solid rises or lowers around the probe, the capacitance field changes. This is monitored and used to control the two onboard relays.

Each relay includes the full differential control to allow the relay to activate and deactivate between two distinct at user determined points on the probe. This can be used for pump and valve control between high and low level points. Adjustable time delay is standard to suppress alarms from turbulence.

Hazardous Location Use

- 2880 Electrical Safety UL, CSA or IEC 61010

- Housing UL/FM/CSA

- Class I, Group B, C, D;

- Class II, Group E, F, G

- Probe CSA Class I, Group C, D

The electronics for this model can also be mounted remote from the probe. The probe becomes Intrinsically Safe when ordered with an IS Barrier installed in the 2852-LS control panel: CSA Div I, Class I, Groups A, B, C, D

Capanivo® – CN 7100 Capacitive Sensor

The Capanivo® 7100 Capacitive Level Detector is used as a full demand or empty detector as well as for leakage detection in any kind of liquid. Due to its compact design, the sensor is ideal for small containers or tubes. Even aggressive media will be reliably detected due to the resistant materials. Even measurement from the outside and thus without direct contact with the medium is possible.

- Simple commissioning without adjustment to the medium

- “Tip Sensitivity” allows measurement from the outside as well as use in both metallic and non-metallic containers

- Reliable measurement results even with strongly adhering material

Explosion Proof Magnetostrictive Float Level Transmitter MPX-E/R

Extreme Accuracy For Extreme Environments

The MPX-E’s lightweight design makes it ideal for limited space applications, while the MPX-R’s large, robust floats and stem make it ideal for harsh applications where fouling or build-up might be a concern.

The MPX Magnetostrictive Liquid Level Probe is very accurate and tough as nails. It’s also an ideal solution for taking two measurements: both the interface level measurement and the total volume.

Modbus Output: The RS-485 Modbus RTU output makes the MPX compatible with any Modbus controller or PLC. It also simplifies wiring dramatically.

Tank Cloud Compatible: The MPX liquid level sensor is a Tank Cloud slave sensor, able to communicate via the Internet with the addition of an LOE Master sensor or an RST-5003 module.

Durable & Compatible: This liquid level sensor is built to take a beating – designed for high turbidity environments in hazardous locations. It also has several material options for the stem and floats for maximum chemical compatibility.

M5600 Single Point Level Switch

The M5600 single point level switch is designed specifically for equipment applications requiring durability. This stainless steel float switch provides many years of trouble-free switching in even the harshest conditions. Designed for industrial applications, this switch is ideal for food or water applications and can be field configured for normally closed or normally open switch operations.

|

Model # |

M5600 |

|

Stem Material |

316 Stainless Steel |

|

Float Material |

316 Stainless Steel |

|

Mounting |

1/4″ NPT |

|

Max. Pressure |

200 psi |

|

Max. Temperature |

392°F / 200°C |

|

Electrical Ratings |

240V AC, 0.40A; 120V AC, 0.50A; 120V DC, 0.20A; 24V DC, 0.50A |

|

Approvals |

CE, UL Haz. Loc., CSA Haz. Loc., NSF |

PRESSURE

Series H3 Explosion-Proof Differential Pressure Switch

A heavy-duty, industrial unit with a unique new design which provides sensitivity to differential pressures as low as 10″ of water (254 mm w.c.) yet handles a total pressure of 1500 psi (103 bar). Unlike common differential pressure switches that use a piston type motion transfer, the Series H3 utilizes a rotary motion transfer shaft that prevents a change in total pressure from causing a set point shift.

Unit yields deadbands approximately 5% of range, with zero set point shift due to variation in working pressures. Friction is minimized and repeatability is increased by allowing the range spring to act directly on the diaphragm plate. Rolling diaphragm design maintains a constant effective area to further reduce friction. Diaphragm is allowed to “seat”, allowing application of full rated pressure, up to 1500 psi (103 bar), on either high or low pressure port, without damage. Special over-travel feature prevents overtightening of range adjust screw. Choose an optional 316 SS chamber for water and water-based fluids or harsher applications.

Series 1950 Explosion-proof Differential Pressure Switch

Compact, Low Cost, Explosion-proof and Weatherproof

The Series 1950 Explosion-Proof Differential Pressure Switch combines the best features of the popular Dwyer® Series 1900 Pressure Switch with an integral explosion-proof and weatherproof housing, making it an exceptional value for either application.

It is CE, UL and CSA listed, FM approved for use in Class I, Div 1, Groups C and D, Class II Groups E, F, and G and Class III hazardous atmospheres (NEMA 7 & 9), Raintight NEMA 3 (IP54). Weatherproof features include a drain plug and an O-ring seal in the cover. Electrical connections are easily made by removing the front cover. For convenience, the set point adjustment screw is located on the outside of the housing. Twelve models offer set points from .03 to 20 in w.c. (0.0075 to 5 kPa) and from .5 to 50 psi (0.035 to 3.5 bar). The unit is very light and compact – about half the weight and bulk of other explosion-proof or weather-proof switches with separate enclosures.

Smart Gauge Pressure Transmitter Model: PTG71/PTG72

Azbil provides various types of pressure transmitters developed using technologies based on a long-developed performance record.

Azbil Model PTG71/PTG72 Smart Pressure Transmitter is a high-performance, highly reliable gauge pressure transmitter. Based on Azbil Corporation’s proven Smart Transmitter technologies, the transmitter offers improved performance and reliability with size, weight, and cost advantages. An optional built-in digital indicator allows the pressure transmitter to be used in a wide variety of applications.

The Model PTG71/PTG72 Smart Pressure Transmitter can also execute two-way communications between model SFC (Smart Field Communicator), or HART® communicators, and, via DE protocol, a TDC3000 or 3000X and a database, thus facilitating self-diagnosis, range resetting, and automatic zero adjustment operations. Any range can be set using the Smart communicator or the HART communicator option. These further increase range flexibility and keeps inventory down. CE Marked. Water and dustproof for IEC IP67, TIIS Explosion-proof, FM Explosion-proof, FM Dust-ignition-proof, KCs Flame-proof, NEPSI Flame-proof, and NEPSI Dust ignition-proof models available.

TEMPERATURE

WINSMART™ TY52 Smart Explosion Proof Temperature Transmitter

Integrated temperature transmitter with ASIC signaling transmitter

- Explosion proof smart temperature transmitter for hazardous locations

- -50 to 400°C (-58/752°F ) measure range

- 0.5% accuracy

- Simple to operate 3-push button control

- HART® or Modbus communications are available

- Low power option available

- Re-zero function for safe field calibration

- 5-year warranty

The TY52 can be utilized and installed anywhere where temperature measurement is required. From Oil & Gas installations to Power Generation, this product has a rugged design and is equipped with the communication protocols to meet all your day-to-day requirements.

TTE Explosion-Proof RTD Temperature Transmitter

User Selectable Ranges, Optional LCD Display

Series TTE Explosion-Proof RTD Temperature Transmitter is the ideal product for hazardous temperature measurement applications. The TTE series has seven pre-programmed temperature ranges that are selectable via an internal dip switch. For those applications that need a custom range, the transmitter can be easily configured for any range between -30 to 250°F with a minimum span of 40°F. The span and zero can be quickly adjusted with a simple push button design. The compact housing allows for the transmitter to be mounted in virtually any application.

Series HHT Hazardous Area Humidity/Temperature Transmitter

Intrinsically Safe or Explosion-Proof Models

The Series HHT Hazardous Area Humidity/Temperature Transmitter takes accurate measurements in the harshest of environments. The explosion-proof model is offered with 4-20 mA output for humidity only. The intrinsically safe version is offered with 4-20 mA output for humidity and temperature and does require an intrinsically safe barrier to meet hazardous area approvals.

GAS DETECTION

The TracXP TXP-T40 transmitter is a highly configurable fixed gas detector supporting single or dual sensor applications in Class 1 Division 1 or Class 1 Division 2 environments. Local and remote sensor options allow the TXP-T40 to adapt to a wide variety of industrial applications.

- Certified for Class 1, Div. 1 or Div. 2

- Vivid QVGA Backlit Color TFT Display

- Brilliant Status Indicating Color Display

- Standard Ethernet Port with Web Server

- Modbus TCP

- Dual Smart Sensor Capable

- Non-intrusive One-Man Calibration

- 3 Programmable Relays and Fault Relay Available

- Aluminum and Poly Black Enclosures Available

INTRINSICALLY SAFE (Class 1 Div 1/Zone 0)

LEVEL

Series PBLTX Submersible Level Transmitter

The Series PBLTX Submersible Level Transmitters are manufactured for years of trouble-free service in the harshest applications. These Series measure the height of liquid above the position in the tank referenced to atmospheric pressure. The transmitter consists of a piezoresistive sensing element, encased in a 316 SS housing with cage and large diameter 316 SS diaphragm seal.

- Meet application requirements with a durable cage design with a large diameter 316 SS diaphragm seal that is non-clogging and damage resistant to floating solids

- Increased life with lightning and surge protection utilizing dual arrestor technology, grounded to case, eliminating both power supply surges and lightning ground strike transients (surge protection is not guaranteed and is not covered by warranty) on PBLT2 models Series PBLT2 & PBLTX Submersible Level Transmitter

- Eliminates particulate or water droplets from entering the transducer using a maintenance-free filter

- Peace of mind with cULus approved intrinsically safe on PBLTX models for use in hazardous locations when used with proper barrier

- Decrease ownership cost with durable, 270 lb tensile strength shielded and vented cable and excellent chemical compatibility

- Flexible installation options with NPT connection to rigidly install in a pipe/conduit or use an A-625 hanging loop to attach a chain to remove from the installation

Series SBLTX Submersible Level Transmitter

Perfect for Ground Water and Wells, Lightning Protected or Intrinsically Safe

The Series SBLTX Submersible Level Transmitters are manufactured for years of trouble-free service. These series measure the height of liquid above the position in the tank referenced to atmospheric pressure. The transmitter consists of a piezo-resistive sensing element, encased in a 316 SS housing.

SBLTX Compliance: cULus intrinsically safe for Class I, Div. 1, Groups A, B, C, D; Class II, Div. 1, Groups E, F, G; Class III

Div. 1;

- Well monitoring

- Groundwater monitoring

- Environmental remediation

- Surface water monitoring

- Downhole

- Water Tanks

EchoTouch® US06 & US12 Reflective Ultrasonic Liquid Level Sensor Transmitter

The intrinsically safe reflective ultrasonic level transmitter provides continuous level measurement up to 39.3’ (12m) with a 4-20 mA analog signal output and is configured via its integral push button display module or WebCal software. The non-contact liquid level sensor features a proprietary Reflective Technology™ that delivers reliable level measurement in condensing environments. Select this sensor for bulk tanks with non-foaming and mildly vaporous media such as chemicals, water, wastewater and oil. Typical applications include bulk storage, neutralization tanks, clarifiers and waste sumps.

- Offered in 6 m (19.6’) and 12 m (39.3’) measurement ranges

- Reflective Technology™ measures reliably with condensation

- Corrosion resistant PVDF transducer with aluminum enclosure

- Narrow 3” (7.6 cm) beam width for applications with limited space

- LCD display indicates level in inches, meters or percent of span

- Fail-safe diagnostics with selectable fail-safe signal outputs

- Configuration via push button display or WebCal software

- Automatic temperature compensation from -40º to 80º C.

EchoPro® LR11 Radar Liquid Level Sensor Transmitter

The intrinsically safe 26 GHz. pulse radar level transmitter provides continuous level measurement up to 32.8’ (10 m) with a 4-20 mA analog and HART digital signal output, and is configured via its integral push button display module or HART communicator. The non-contact liquid level sensor is intended for chemical or water storage applications in above grade metal or reinforced concrete tanks or below grade tanks of any material. Select this sensor for easy process conditions with corrosive media, light agitation, condensation or vapour, and installation in a low-profile tank adapter or flange fitting. Typical applications include chemical bulk storage and tanker trucks.

- PFA encapsulated antenna and mount for corrosive media

- Configuration via push button display or HART communicator

- 26 GHz. pulse radar is unaffected by vapour or condensation

- 12” (30cm) dead band enables utilization of the entire tank

- LCD displays level in feet or meters with percent of span bar

- Optional display mode indicates the echo signal return curve

- Auto-temperature compensation for accurate measurement

- Fail-safe diagnostics with selectable signal fail-safe outputs

- Recognition, storage and rejection of false echo signal returns

- IP67 stainless enclosure with polycarbonate display window

EchoPro® LR16 Radar Liquid Level Sensor Transmitter

The intrinsically safe 26 GHz. pulse radar transmitter provides continuous level measurement up to 98.4’ (30 m) with a 4-20 mA analog and HART digital signal output, and is configured via its integral push button display module or HART communicator. The non-contact liquid level sensor is intended for petroleum, water, wastewater and diluted chemical storage or process conditions in above or below grade tanks of any material. Select this sensor for challenging process conditions with diluted or non-corrosive media, light surface foam or agitation, higher temperature or pressure, condensation or vapour, and installation in a tank adapter, flange fitting or metal stand-pipe. Typical applications include bulk storage, tanker truck, RO storage, process tank, waste sump and neutralization tanks.

- Rugged 316L stainless steel antenna and process mount

- Configuration via push button display or HART communicator

- 26 GHz. pulse radar is unaffected by vapour or condensation

- 12” (30cm) dead band enables utilization of the entire tank

- LCD displays level in feet or meters with percent of span bar

- Optional display mode indicates the echo signal return curve

- Auto-temperature compensation for accurate measurement

- Fail-safe diagnostics with selectable signal fail-safe outputs

- Recognition, storage and rejection of false echo signal returns

- IP67 stainless enclosure with polycarbonate display window

FLOW

IS Barriers

65800 Series Single Channel Zener Barrier

65800 Series units are exceptionally compact resulting in installation flexibility and simplification; especially in multiples on a common mounting plate. They provide great economy as well since no explosion-proof enclosures are needed for sensor wiring. Encapsulated construction is impervious to dust and moisture.

Single-screw mounting is standard, but units can be supplied with an optional clip for rail mounting. The single through-mounting screw also provides an electrical connection to ground through the earth-grounded mounting surface. Any non-voltage-producing sensor or switch is rendered intrinsically safe for hazardous locations when properly connected to the output of these Zener Barriers.

- Limits DC voltage and current to the hazardous area and provides a path for fault current

- Intrinsic safety with solid-state reliability

- Compact size streamlines installation

- Space-saving in multiples

- Encapsulated construction is impervious to dust and moisture

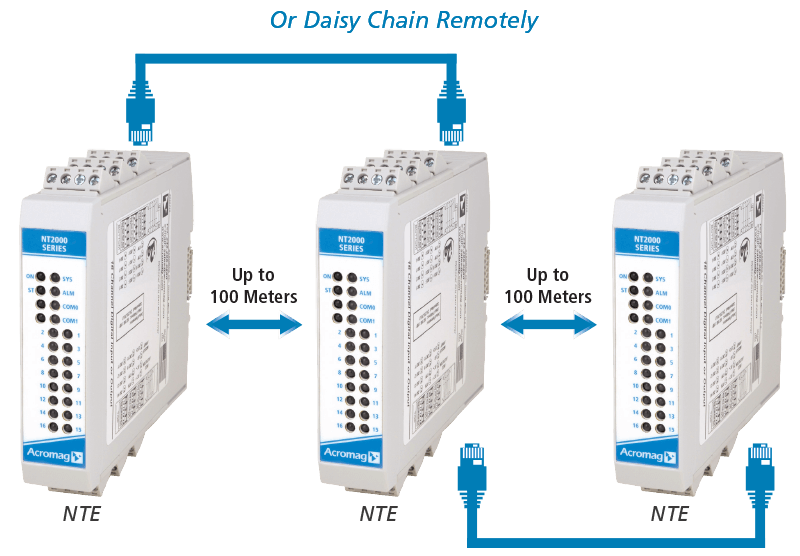

Network Solutions

Multi-protocol support

The NTE Ethernet I/O modules are pre-programmed to support Modbus/TCP, Ethernet/IP and Profinet protocols. Just select which is to be used. Modules also support direct i2o® peer-to-peer communication without a master.

- Integrated I/O expansion bus

- Up to 64 I/O channels per port

- Mix analog, digital, and temperature I/O on one port

- i2o peer-to-peer or multicast communications

- Rugged design, -40 to 70°C

- Hazardous location approvals

Contact Us

Contact Davis Controls today about our state-of-the-art products and experience our expert application advice and reliable service!

CONTACT US