Explore our solutions by clicking on the brand below:

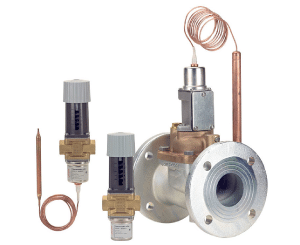

Danfoss’ thermostatically operated valves are a simple and reliable control solution requiring neither electricity nor control air. The range of thermostatic valves includes a series of industrial products for both cooling and heating controls. The valves are self-acting, i.e. they operate without the supply of auxiliary energy such as electricity or compressed air.

Danfoss thermostatic valves are a simple and reliable way to control the temperature in cooling applications. They are typically used in:

- Hydraulic systems

- Bio-mass boilers

- Injection moulding machines

- Compressors

- Vacuum pumps

- Dry-cleaning machines

- Distillation plants

- Other machinery using liquid cooling

- Steam boiler applications

- Autoclaves

Dwyer Instruments is an industry leader in the manufacturing of instrumentation solutions for the HVAC and Process Automation markets. With a long history of innovation in designing and manufacturing measurement sensors that provide superior product performance, Dwyer products are used every day in critical and essential processes around the world.

Dwyer Instruments is part of the DwyerOmega family of brands. Other DwyerOmega brands include Omega Engineering, known for Temperature Measurement Solutions, Control and Monitoring Solutions, Data Acquisition Solutions, Force & Strain Measurement Solutions, Level Measurement, Flow Instruments, and IIoT Solutions.

Series 16G, 8G, AND 4G Temperature/Process Loop Controllers

Universal Input, Dual Output, On/Off PID or FUZZY Logic Output Control

Series 16G, 8G, AND 4G Temperature/Process Loop Controllers allow for monitoring and control of temperature or process conditions.

The controller features two independent control outputs for dual loop control using on/off, auto-tune or self-tune PID, fuzzy logic, or manual control methods. RS-485 interface is included with Modbus® communication protocol, for easy bench-top configuration or integration with a PLC or data control system.

Series 32B 1/32 DIN Temperature/Process Controller

Universal Input, Dual Temperature Output Control, RS-485 Communication

The compact Series 32B Temperature/Process Controller offers advanced control features for the most demanding temperature or process applications. Enclosed in a 1/32 DIN housing, the Series 32B is designed with dual, 4-digit LED displays for local indication of process value and setpoint. Control methods include ON/OFF, PID, self-tune, and manual tune. PID control is supported with 4 temperature and time (ramp/soak) control actions.

The dual loop output control allows simultaneous heating and cooling control. The second output can be configured as an alarm mode using one of the thirteen built-in alarm functions.

RS-485 communications is standard on the Series 32B. Up to 247 communication addresses are available with transmission speeds of 2400 to 38,400 bps. The controller also features universal input, selectable temperature units (°F/°C), selectable resolution, quick sampling rate and security protection.

Series 16A Temperature/Process Controller

1/16 DIN, Universal Input, Fuzzy Logic, Self-Tune PID

Latest microprocessor based technology affords full programmability with a complete array of features in a compact ultra low cost unit. 16A Series Temperature/Process Controller features universal input, Self-Tune PID, Fuzzy Logic, and dual four-digit LED displays for process and set point value. Selectable inputs can be thermocouple, RTD, current or voltage. Available outputs are solid-state relay, relay, pulsed voltage, or proportional current Programmable alarm (optional) can be reset automatically or manually.

The front panel is waterproof and corrosion resistant (UL type 4X), making it ideal for sanitary applications. Replace electronics without wiring changes (via removable front panel). Self diagnostics, non-volatile memory and selectable control modes are all designed for greater productivity. Four security levels are password protected. On-off, P, PI or PID manual tune control functions can be selected or the controller will Self-Tune automatically for best PID control.

In addition to the features listed above, the 16A offers Peak/Valley indication, Percent Output indication, Digital Input Filter, and a host of others.

Series 8600 Temperature/Process Controller

1/8 DIN Self-Tune PID, Fuzzy Logic Software

The Series 8600 Temperature/Process Controllers set a new standard for quality, ease-of-use and value. While a high level of standard features are included, many function setup items appear in the control menu only when the function is selected, so you don’t have to wade through unnecessary items. Units feature a universal input for thermocouple types J, K, E, T, L, N, B, C, S, & R; RTDs – 100Ω Plt. NIST, 100Ω Plt. DIN, 120Ω Ni Industrial, 1000Ω Plt. DIN; differential input (-10 to +10 mV DC) and process input (0 to 20 mA DC, 0 to 10 VDC). A standard 24-volt isolated, regulated power supply is included to operate most standard 4-20 mA transmitters.

Standard features include Self-Tune, Fuzzy Logic, fully adjustable PID, Auto/Manual control with bumpless transfer and front panel activation key, percent output indication, peak and valley indication, loop break protection and indication. For process inputs, the display is fully programmable from -1999 to +9999 with a selectable decimal point location. Most thermocouple and RTD inputs can show whole or tenth-degree displays. The Series 8600 is available with single or dual setpoint outputs and can be programmed for on-off, PID or heat/cool or latching alarm. All outputs are isolated from the inputs. Outputs include a 10 amp relay, 2.5 amp SSR and 0-20 mA DC (scalable). 15 VDC SSR drive is standard.

Series 4B 1/4 DIN Temperature/Process Controller

Dual Control Output, RS-485 Communication, Auto-Tuning

The Series 4B 1/4 DIN Temperature/Process Controller is designed to accept thermocouple, RTD, current or voltage input and provide dual outputs for control. Available outputs include relay/relay, voltage pulse/relay, current/relay, or linear voltage/relay.

The units can be programmed for ON/OFF, PID, auto-tuning, or manual tuning control methods. The PID control is supported by 64 ramp/soak actions. The Series 4B also includes two additional alarm outputs. The second relay output can be reconfigured as a third alarm output. The alarm type can be selected from 13 different preprogrammed alarm functions. The controller features dual LED displays for local indication of process and setpoint values.

Series SCD DIN Rail Temperature/Process Controllers

Universal Inputs, Up to 8 PID Loops, Modbus® Communications

The Series SCD DIN Rail Temperature/Process Controllers offer multiple PID loops in a compact size. Each SCD-1000 master controller can be combined with up to seven SCD-2000 slave controllers without any wires. Each controller has one universal input, one relay output and one user selected output.

SERIES DCT1000 DUST COLLECTOR TIMER CONTROLLER

Modular Design, User Friendly, Up to 22 Channels

The SERIES DCT1000 Dust Collector Timer Controller simplifies on-demand cleaning requirements by eliminating the need for external devices such as pressure switches, relays, and timers. The modular design allows for use as a continuous cleaning control or on-demand cleaning control using the optional plug-in pressure module. The DCT1000 is the same size for 6, 10, and 22 channels, allowing one board size to be the standard on one enclosure.

Small Format Products

All DYNICS Flat Panel Monitors, Computer Modules, Integrated Workstations and Rackmount Chassis are designed and built to withstand high vibrations, temperature extremes, and the harshest industrial environments.

Choose from an extensive selection of Industrial Computers to better match your industrial needs.

Large Format Products

DYNICS offers the most comprehensive line of industrial computers and large LCD industrial signage products available today.

JUMO is one of the leading manufacturers in the field of industrial sensor and automation technology. This innovative product range includes the entire measuring chain from sensors to automation solutions for temperature, pressure, liquid analysis, flow rate, filling level, and humidity.

JUMO pressure measurement products include pressure sensors, transducers, switches and differential pressure transmitters. Various output signals, different process connections, materials for process connections and sealing material are available.

The pressure transmitter with silicon sensor is used to detect the relative pressure (0 to 0.25 bar – 0 to 25 bar) in liquid and gaseous media. The pressure transmitter measures the pressure and converts it into an electrical signal with a deviation from the characteristic line of ≤ 0.5 % from the end value. A two-wire current signal, three-wire voltage signal, or a ratiometric output signal can be selected for the electrical signal output. These should be supplied with the appropriate DC voltage (nominal DC 24 V).

Kistler-Morse® designs and manufactures total weighing systems for bulk and in-process applications.

- Sensors: Weighing sensors have the ability to turn vessels into scales and are ideal for conditions ranging from sanitary to rugged outdoor environments. Kistler-Morse’s offering includes bolt-on sensors, load stands and load cells.

- Controllers: Kistler-Morse® offers single and multi-vessel weighing controllers so that customers can monitor and provide stable and accurate readings.

- Inventory Management Solutions: Dry-bulk inventory management solutions can gather and transmit real-time inventory data via the Internet in order to provide customers with a reliable means of material monitoring and management.

KM products can be found at work throughout the food, aggregate, plastics, power, chemical and biotech industries, in virtually every type of vessel. Kistler-Morse® products are built tough to withstand the most rugged applications while providing companies with the accuracy they need.

Human Machine Interfaces (HMIs)

Human machine interfaces (HMIs) are devices and software for monitoring and operating automation facilities using graphics designed by users. XGT Panels developed with the Windows CE Platform provide user-oriented convenience, clear and realistic expressions, speedy data transmission and treatment, and software familiar to users.

LS Industrial Systems has applied an easy user interface, cutting-edge graphic technology, and other innovative technologies that include fast and stable network functions to XGT InfoU, an HMI-based software program.

- Responsive touch screen

- Dual-Core CPU offers high-speed communication and processing

- Multiple interface methods to cope with the Internet of Things

- Multi-touch and gesture-control screens

- Reinforced protection against water and dust

- Conforms to NEMA 4X standard.

- One-to-one interchangeability with existing iXP series

Programmable Logic Controllers (PLCs)

Programmable logic controller (PLC) is a general-purpose control device that automatically controls machinery, facilities, and assembly lines by user defined programs. It also has a variety of communication functions for sequence, motion, and process control.

XGT Series (XGK, XGI, XGR)

The XGT series incorporates the latest technological achievements in Programmable Logic Controllers by experience and dedication to quality in design and manufacturing.

- XGK: Ladder Programming

- XGI: IEC Standard Programming

- XGR: Redundancy System

XGB Series

The XGB is a micro PLC that offers maximum performance at minimum cost. With its high functionality, XGB supports simple control systems to complex tasks. Strengthening its communication functions, XGB offers user-oriented integrated control.

XBC/XEC U-Type

- Max. 352 I/O points – Max. 2 communication modules

- RS-232C, RS-422/485, Ethernet, CANopen, Profibus-DP, DeviceNet, EtherNet/IP, RAPIEnet

- Data logging function

- SD memory format, FTP link, Diagnosis

- Dualport Etherenet

- 2-port Ethernet switch

- FTP server support – Web Server – PLC monitoring – Time Synchronization

- E-mail service

LUTZE SUPERFLEX ® PROFIBUS (C) PUR, Shielded

High Flexing PROFIBUS Cable for Continuous Motion Applications

- For the cabling of industrial field bus systems like PROFIBUS DP, SINEC L2, F.I.P.

- For continuous flexing applications in drag chain or free movement in automation technology, transport and conveyor technology, machine tool manufacturing

- Compatible with all major drag chain brands

- Compliant with NFPA 79 requirements

- High protection against electromagnetic interference (EMI)

- Talc and silicone free

LUTZE SUPERFLEX® DeviceNet™ BUS (C) PUR, Shielded

High Flexing DeviceNet™ Cable for Continuous Motion Applications

- For the wiring of industrial devices, sensors and control devices

- For continuous flexing applications in drag chains or free movement in automation technology, transport and conveyor technology, machine tool manufacturing

- Compatible with all major drag chain brands

- Compliant with NFPA 79 requirements

- 2-pair cable: The pair with the smaller cross section is for data transmission, the pair with the larger cross section is for the power supply

- High protection against electromagnetic interference (EMI)

- Talc and silicone free

LUTZE MOTIONFLEX ® ETHERNET (C) TPE, Shielded

Flexing Ethernet Cable for Linear and Twisting Motion Applications

- For the cabling of industrial Ethernet systems

- Cable design for harsh industrial environments and operating conditions with high noise levels.

- Automation technology, material handling, conveyor technology, and industrial machinery

- Suitable for motion applications with repetitive movement, flexing, and torsional stress

- Compliant with NFPA 79 requirements

LUTZE SUPERFLEX® ETHERNET (C) PUR, Shielded

High Flexing Ethernet Cable for Continuous Motion Applications

- For the cabling of industrial Ethernet systems

- Cable design for harsh industrial environments and operating conditions with high noise levels

- Applicable in automation technology, transport and conveyor technology, machine tool manufacturing

- For continuous flexing applications in drag chains or free movement

- Compatible with all major drag chain brands

- Compliant with NFPA 79 requirements

LUTZE DRIVEFLEX ® XLPE (C) PVC, Shielded

Flexible VFD Cable XHHW-2 for Stationary Applications

Dual-shielded motor supply cable to connect power to 3-phase motors, VFDs and servo drives

- Cable design for harsh industrial environments and operating conditions with high noise levels

- Thermoset XLPE insulation offering superior overload and short-circuit temperature

- Type XHHW-2 insulation offering smaller ODs for general VFD applications

- Compliant with NFPA 79 requirements

- TC-ER-JP for use with cable trays without conduit, which can reduce installation costs in industrial environments

- WTTC – wind turbine tray cable rating for use in wind power generation

- Dry, damp or wet conditions

- Flexible XLPE conductor design

- Reduced cable ODs

- High insulation resistance

- Low capacitance cable

- Effective dual layer shield for EMC compliance

- Oil resistant jacket designed for easy stripping

- Non-wicking fillers

- Ecolab certified resistance to common cleaning agents and chemicals used in food and beverage washdown procedures

- Crush impact resistant

- Gas/vapor-tight sheath per UL 1277

- Sunlight resistant

- Flame retardant

- Direct burial

- Talc and silicone free

LUTZE DRIVEFLEX® XLPE (C) 2 TSP PVC, Shielded

Flexible Composite VFD Cable with two Control Pairs for Stationary Applications

Dual-shielded motor supply cable to connect power to 3-phase motors, VFDs and servo drives

- Cable design for harsh industrial environments and operating conditions with high noise levels

- Thermoset XLPE insulation offering superior overload and short-circuit temperature

- Increased wall thickness insulation type RHW-2, offering lower capacitance and higher impedance making it ideal for applications with high voltage spikes and long cable runs

- Compliant with NFPA 79 requirements

- TC-ER-JP for use with cable trays without conduit, which can reduce installation costs in industrial environments

- WTTC – wind turbine tray cable rating for use in wind power generation

- Dry, damp or wet conditions

- Flexible XLPE conductor design

- High insulation resistance

- Low capacitance cable

- Effective dual layer shield for EMC compliance

- Oil resistant jacket designed for easy stripping

- Non-wicking fillers

- Ecolab certified resistance to common cleaning agents and chemicals used in food and beverage washdown procedures

- Crush impact resistant

- Gas/vapor-tight sheath per UL 1277

- Sunlight resistant

- Flame retardant

- Direct burial

- Talc and silicone free

Automation Series Conveyors

Automation systems require flexibility, precision, and speed. Automation Series conveyors were designed to meet the needs of these types of systems. They are versatile, lightweight and designed with you in mind. The Industrial Series and HydroClean Series conveyors are suited to meet the more specific needs of the automation industries.

QC Conveyors’ Automation Series Conveyors are the ultimate “user-friendly” conveyor. Hi-tech features like Pivot™ rotatable drives, Tension Release™ tool-less belt changes, and a moveable center drive were designed to make your job easier and give you more time to focus on things other than conveyors.

Modular Plastic Chain Conveyor Systems

Flextrac™ Series modular plastic chain conveyors fit the curves and elevation changes of your plant with the flexibility to be easily reconfigured when those things change. Multiple curves, inclines and declines can be included in a single conveyor.

Gripper Elevator Conveyor Systems

The product is gripped between two parallel conveyors and elevated or lowered to a different level of your plant, over an aisle or to remove product from a puck.

Object Detection

SEcure COMmunication Made EAsy. Imagine providing secure remote services to your customers as if you were onsite. Save time, travel costs and provide instant services simultaneously. An Internet based industrial communication solution that helps you monitor, manage and service your equipment no matter where it is located – across town or around the world.

Solutions that give you the ability to reduce costs, improve customer satisfaction and boost revenues by meeting the demands for increased uptime and data collection, all while complying with international cybersecurity standards.

Third generation VPN technology enables Secomea’s IIoT solutions to be:

- Used by non-IT people

- Installed by non-IT people

- Managed by non-IT people

Next Gen Industrial Panel PC

Panel PCs which have a completely fanless design and 6th Generation Intel Core i mobile Processors.

The PC is available with 6 different Display Sizes. Depending on the mounted Display, the Resolution is 1024 x 768, 1280 x 1024 or 1920 x 1080 Pixel.

The PC is equipped with an embedded 3.5″ Processor Board. It comes with a Core i3 Processor with a Benchmark of 3498. Core i5 with a Benchmark of 3898 or a Core i7 with a Benchmark of 4750 options are available.

- A 2.5″ Flash Disk with 120 GB capacity.

- System Memory of 8 GB or optional 16 GB.

- The PC can be booted up from the USB Port.

- Two LAN Ports, up to four serial and five USB Ports, plus a USB 3.1 Port take care of the external interfacing. An external monitor can be connected to the Display Port.

The PC is available with a Stainless Steel Panel Mounted Front Bezel. The System offers a Front with IP 65 Protection and a Touchscreen or protective Glass. UTICOR also offers customer specified solutions.

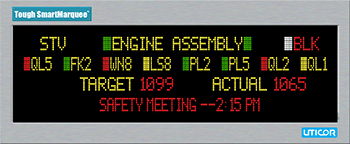

Marquee with the Intelligence of an HMI

Uticor Marquees have been used in plants throughout the world, particularly in the automotive, steel, tire, canning, brewery and cement plants. Tens of thousands of Uticor Marquees have worked flawlessly in General Motors, Ford, Chrysler, Mitsubishi and Toyota plants displaying crucial information to plant personnel in their press and paint shops. Uticor has consistently ranked among the very top suppliers of Alpha-numeric message displays.

Uticor Products go through HALT (Highly Accelerated Life Test) to identify and eliminate components/areas likely to fail prematurely. HALT-HASS process simulates product life over the next 20 years of operation.

In addition to matched LEDs, Uticor products go through a 96 hour burn-in period to eliminate infant mortality of thousands of LEDs in a typical marquee. A 4 line 40 Character marquee has 7,680 individual LEDs. Even a 0.05% infant mortality (typical of LEDs and other optoelectronic semiconductors) could have four bad LEDs. 96 hour burn-in assures heating out the weak LEDs before the Tough SmartMarquee is shipped to you.

West Control Solutions is part of Gems Sensors & Controls and is home to PMA, West Instruments and CAL Controls.

Partlow Electronic products – together with the CAL, PMA and West product brands form West Control Solutions. CAL Controls is a leader in the Life Sciences and Laboratory market segments.

From simple, entry-level temperature controllers to highly sophisticated, functionality-rich solutions, West Control Solutions offers a variety of easy-to-use products to meet the demands of all control applications. Our comprehensive product portfolio includes single and multi-loop controllers, limit devices, indicators and transmitters along with recorders and tools for data acquisition.

Partlow Electronic Products specializes in a range of DIN temperature and process controllers which offer PID control.

The range also includes a number of limit controllers. In addition to instruments for temperature control, Partlow provides a comprehensive selection of line chart, point chart, circular chart and paperless recorders. The recorders offer flexible charts from basic through to advanced recorders that include programming functionality for up to four loops and up to 16 profiles. The chart sizes range from 10″ to 12″ diameter.

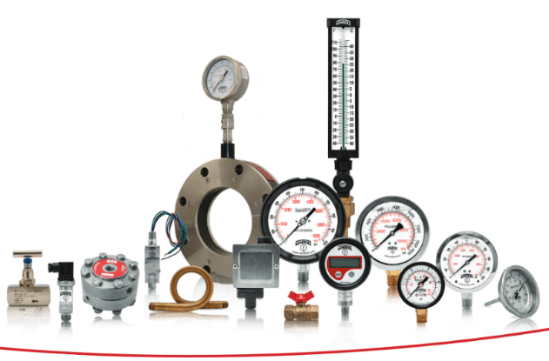

Made in Canada – Winters Instruments manufactures quality-built instrumentation for all markets that require pressure and temperature measurement including pressure gauges, thermometers, diaphragm seals, transmitters, switches and accessories.

WINSMART™ Pressure Transmitter

- Explosion proof smart pressure transmitter for hazardous locations

- Built-in temperature sensor

- 0.2% standard; 0.5%, 0.1%, 0.075% or 0.05% optional

- Simple to operate 3-push button control

- HART or Modbus communications available

- Low power option available

- Re-zero function for safe field calibration

- Wide range of accuracies and turndown ratios allow for installation in any application setting

- CRN Pending

- 5 year warranty

WINSMART™ LY36 SMART EXPLOSION PROOF DIFFERENTIAL PRESSURE TRANSMITTER

Applications:

- Pressure monitoring for oil and gas

- Well head process control

- Petrochemical installations

- Power generation equipment and

- All hazardous locations.

Contact Us

Contact Davis Controls today about our state-of-the-art products and experience our expert application advice and reliable service!

CONTACT US