KATflow

Non-invasive flowmeters work on the transit time ultrasonic principle. This involves mounting a matched pair of transducers on the external surface of the pipe, which are then used to generate ultrasonic pulses. These signals travel through the pipe wall and liquid media from one sensor to the other, both with and against the direction of flow.

The key principle of the method applied is that sound waves travelling with the flow will move faster than those travelling against it. The difference in the transit time of these signals is directly proportional to the flow velocity of the liquid and consequently associated flow values.

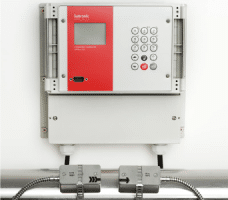

KATflow 150

KATflow 150 is an advanced ultrasonic flowmeter for permanent installation. The dual-channel design allows for two independent measurements simultaneously or two pairs of transducers on a single pipe for locations where there are non-ideal conditions.

With high temperature flow transducers rated to 250°C, a quick set-up wizard and ten plug-in card slots, the KATflow 150 is the most versatile transit time meter available. Communication options are RS485, Modbus RTU/TCP/IP, BACnet, HART, Profibus, Profinet and Ethernet. Outputs are 4-20 mA, pulse and relay. The transmitter accepts temperature inputs for complete energy calculations and pressure inputs to provide mass flow and information measurements with a built-in data logger.

Katflow 100

KATflow 100 is a compact clamp-on ultrasonic flow transmitter with a robust and practical design for permanent installation and flow measurement on single pipes. The instrument offers a cost-effective option owing to its simplified specification and availability of a range of transducer types. The simple operation of the KATflow 100 makes it the perfect product for large projects and customer specific solutions and includes a built-in data logger.

The KATflow 100 offers a wide range of input, output and communication interfaces and with matched pair temperature sensors provides precision thermal energy measurements and data logging.

KATflow 200

KATflow 200 hand-held clamp-on ultrasonic flowmeter. This lightweight, fully portable flowmeter is small, powerful, incredibly easy to use and can be operated with one hand, which makes it an ideal tool for use in confined spaces or when working at height. The KATflow 200 offers measurement performance normally associated with more complex and expensive devices and is complemented by the exceptional quality and robustness of the Katronic transducers.

KATflow 210

The KATflow 210 is a portable flowmeter designed for situations that require a reliable flow measurement regardless of the conditions in which it operates. With its advanced battery technology and durable waterproof housing, the instrument is intended for long-term installation in remote areas where access to power is limited and exposure to the worst of elements is likely. This device has been further enhanced by the inclusion of a specially manufactured IP 68 version of the K1N stainless steel transducers which increases shock protection.

Applicable for leakage surveys, metering in pits or wet wells where flooding is likely and irrigation systems, this is the most robust portable meter manufactured. Measurable pipe sizes are 1” to 100” and temperatures from -30° to 130°C.

The choice of 4-20 mA, relay and open-collector outputs available on the KATflow 210 allow it to be used as a temporary replacement for existing inline flowmeters when calibration is due. Available with Modbus communications, this unit allows for simple integration to external wireless communications.

KATflow 230

KATflow 230 is easily portable but incorporates an advanced specification for situations which require comprehensive measurement features coupled with easy operation. The flowmeter has two measurement channels, which allow it to monitor two pipes simultaneously or to improve accuracy in non-ideal conditions. The KATflow 230 can also be supplied with a variety of options to meet the most diverse application requirements.

The choice of 4-20 mA, relay and open-collector outputs available on the KATflow 230 allow it to be used as a temporary replacement for existing in-line flowmeters when calibration is due. Moreover, the inclusion of PT100 temperature inputs enables the instrument to provide either temperature compensated flow data or full energy measurement.

Energy Meters: Ultrasonic Flowmeters for Thermal Energy Measurement

KATflow 100. KATflow 150. KATflow 230.

Three of the Katronic clamp-on ultrasonic flowmeters can be supplied as heat quantity measurement instruments and are increasingly being used as portable and permanently installed energy meters by various industries and municipal organizations. The clamp-on mounting technique of the flow and temperature sensors enables the flowmeters to measure heat quantity non-invasively without the risk of interruption of flow, pressure drop or leakage.

The KATflow 150 and KATflow 100 are used for permanent installation on a variety of HVAC applications and can easily be embedded into automated building management and control systems. The portable KATflow 230 is employed for spot measurements as part of energy consumption surveys. All of the energy meters offer process outputs including current outputs, open-collector outputs with totalizer pulse, and digital relay outputs. Additionally, the KATflow 150 and 100 can be equipped with an RS 485 or Modbus for ease of integration.

- External temperature and heat quantity measurement

- Clamp-on PT100 temperature sensors

- Up to 100,000 measurement data logger and software for sampling and data transfer

- Setup wizard for easy and quick meter programming

- Bi-directional flow measurement

Specifications

- Pipe diameters range from 10 mm to over 3,000 mm

- Temperature range for sensors from -30°C to +250°C (-22°F to +482°F)

- Meters can be used with a variety of insertion PT100 sensors

- Measurements in W, kW, MW for heat flow, and J, kJ, MJ for heat quantity

- Three-line display can show heat flow and both temperature measurements

- Measurement of refrigerants and water glycol blends