LEVEL

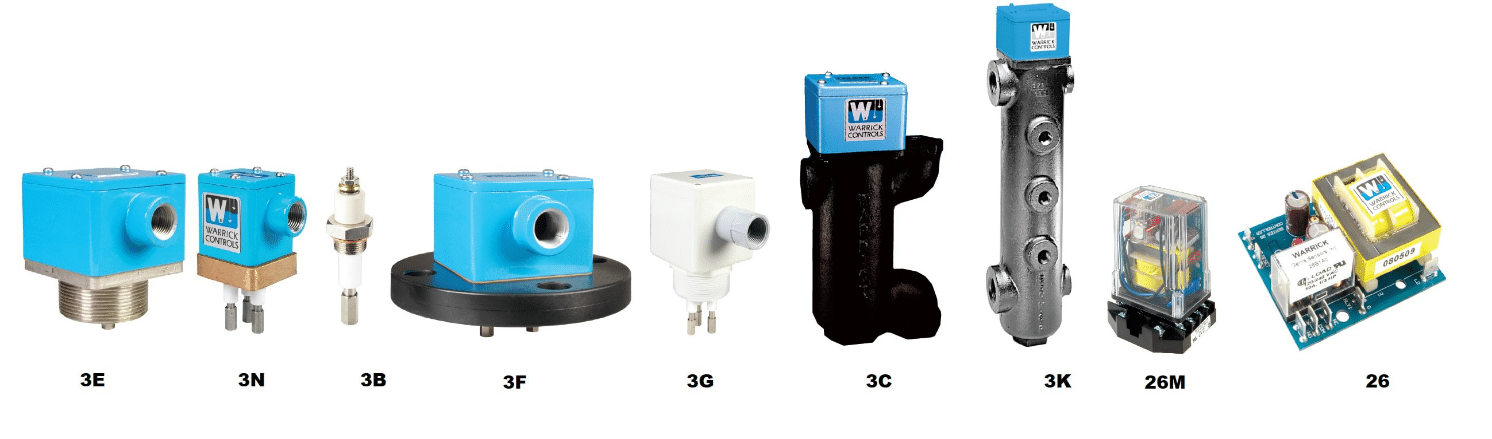

Warrick Conductivity

Conductivity Controls provide a dependable, no-moving-parts control and monitoring of conductive liquids. Conductivity controls offer reliability, process automation, labour savings, flexibility and operator safety at economical cost. Take advantage of a liquid’s conductive properties to complete a circuit and cause a control relay to actuate. The use of permanently mounted stationary electrodes gives the user precise accuracy, repeatability and no-moving-parts reliability.

- Control/Relay: an electrical device with contacts that open and close in response to liquid levels sensed by the probes. Because it is wired directly to the power source and the sensing source, it can send signals that activate or deactivate solenoids, pumps, alarms or pressure switch devices.

- Fitting: housing that holds the probes (or floats), insulates them from the vessel, and provides a means of connection to the control. Warrick® fittings are available for single-probe or multi-probe applications, for mounting to vessels in a variety of ways, and in open or pressure tight styles.

- Probe: a sensor that extends downward from the fitting, with the tip positioned precisely at the level where the control should be activated. Stainless steel electrodes can be cut to the desired length.

Gems/Warrick conductivity controls provide alarm, pump-up or pump-down control in electrically conductive liquid.

Available in a vast range of sizes, mountings and materials. Gems offers the broadest selection of float type level switches anywhere. Using a proven reed switch design, float type switches deliver long, trouble-free service with precise repeatability. They are available in both single-point and multi-point configurations. Multi-point switches monitor up to six levels with a single unit; lengths from a few inches (centimetres) to 10 feet (3 m).

Electro-Optic

Industry’s largest selection of electro-optic liquid level sensors. Solid-state switching and no moving parts ensures dependability over a long service life.

High Purity

Capacitive

ULS-200 SOLID-STATE POINT LEVEL SENSOR

A highly advanced and durable sensor designed for use in aqueous, oil, and hydrocarbon applications. With a wide temperature and pressure range, it is tolerant of coating and build-up, making it an ideal choice for tough environments. Its solid-state technology ensures a longer life expectancy and a more reliable performance. Standard configurations include a range of time delays for greater customization and flexibility.

- Reliable – Accurate and repeatable point-level detection using advanced sensing technology with electronic solid-state switching

- Durable – Withstands harsh conditions and outdoor environments with IP6K9K rating, wide temperature range, and high-pressure capability

- Versatile – Reduces inventory and simplifies product selection by replacing several different sensor types with the ULS-200 for aqueous, oil, and hydrocarbon-based media

- Time Delays – Standard configurations include: No delay, 3 sec, 5 sec, or 10-second time delays

INDICATORS

Pop the cap, pull the tab and up comes the tape to tell you exactly how much liquid remains in the tank or drum. Ideal for hazardous areas, DIPTAPE and DRUMTAPE indicators are non-electric, plus liquids and vapours remain sealed from the atmosphere. DIPTAPE indicators are designed for tanks. DRUMTAPE indicators fit 30 or 55-gallon storage drums.

PRESSURE SENSORS/TRANSDUCERS

Sputtered Thin Film

Sputtered thin film technology provides years of worry-free measurements under demanding conditions. Ideal for harsh applications demanding long-term service where precise laboratory type measurements are required.

Capacitive

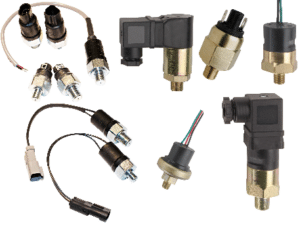

SWITCHES

Piston/Diaphragm

FLOW SENSORS/INDICATORS

RotorFlow®: These highly visible, paddle wheel designs offer accurate visual indication, flow rate sensing and switching. The visual indication is combined with a choice of either pulsed DC output 0-10 V DC analog or adjustable 1 Amp switched output. Available with brass, stainless steel or hydrolytically stable polypropylene housings.

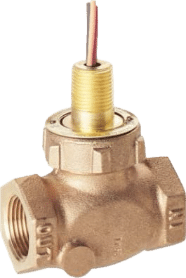

Piston Switch

Proven piston switch technology delivers high repeatability and precise calibration for liquids or gases. Special capability versions offer viscosity compensation and high pressure handling to 1,500 PSIG (103 bar). Brass, plastic or stainless steel bodies.

Proven piston switch technology delivers high repeatability and precise calibration for liquids or gases. Special capability versions offer viscosity compensation and high pressure handling to 1,500 PSIG (103 bar). Brass, plastic or stainless steel bodies.

Paddle Switch

Shuttle Switch

For monitoring water and oil – in line sizes 1/2” to 3” (2.5 to 7.6 cm). Accurate with 1% repeatability and low-pressure drop. Plastic, bronze, stainless steel and marine grade housings.

Pressure Sensors & Transducers

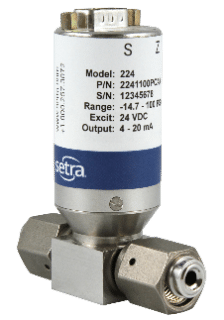

Setra Systems designs and manufactures premium pressure sensors. For over 50 years, Setra has developed a unique understanding of pressure sensing technology and their team of engineers designs some of the most robust, accurate, and reliable capacitive sensing transducers available.

- Differential Pressure Sensors: Setra’s differential pressure sensors are known for their quality and reliability. Designed with premium capacitive sensing technology, Setra offers single-range and multi-range (field selectable) pressure sensors. Capable of measuring both liquid and gases, Setra has the product to meet a breadth of HVAC applications and can be trusted in your most critical applications.

- Absolute Pressure Sensors: Absolute pressure is measured relative to a full vacuum. In contrast, pressure that is measured against atmospheric pressure (also known as barometric pressure) is called gauge pressure. A full vacuum has an absolute pressure reading of 0 PSIA and the average barometric pressure at sea level is ~14.7 PSIA

- Gauge Pressure Sensors

- Ultra High Purity (UHP) Pressure Transducers

- Barometric Pressure Sensors: Barometric pressure sensors are designed to measure changes in atmospheric pressure. Setra’s line of barometric pressure transducers are trusted in some of the most demanding applications including weather stations, data buoys, aircraft altimeter re-certification, and wind assessment and high-altitude research balloons. When accuracy and stability matter, choose the barometric pressure transducers trusted by multiple Government organizations including the FAA and NOAA.

Compound Pressure Transducers: allows users to measure both negative and positive pressure. Compound pressure transducers are zeroed to atmospheric pressure. Applications for compound pressure transducers include HVAC/R equipment, industrial compressors, and water pumps. Setra Systems offers a full line of rugged, reliable, and accurate compound pressure sensors.