For a free quote, fill out our MLG Product Checklist

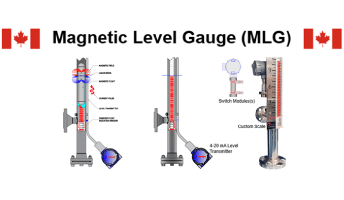

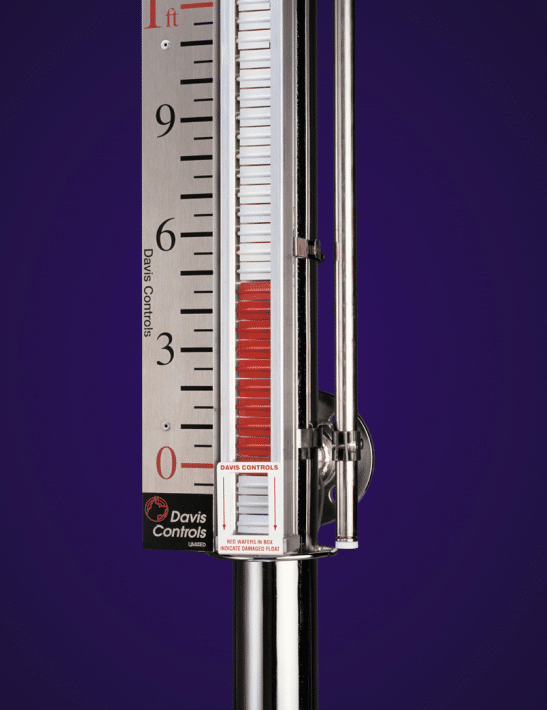

Made in Canada and used throughout North America in a vast range of industries, the Davis Magnetic Level Gauge is particularly suited to applications where hazardous liquids or gases are in use. All of these instruments are made to order and our engineers will provide expert guidance on the design and manufacture of the Magnetic Level Gauges for specific applications.

Davis Magnetic Level Gauges provide immediate and accurate response to level changes, giving clear and sharp legibility over the full range of the liquid level. Local and remote display as well as CSA approved Class1Div1, point level switches are available from stock.

The Davis Magnetic Level Gauge is particularly suitable for duties where dangerous and toxic liquids or gases are involved and where the following features, benefits and options are required:

- Continuous indication of liquid level, local and remote display

- Point switching

- No leakage to atmosphere

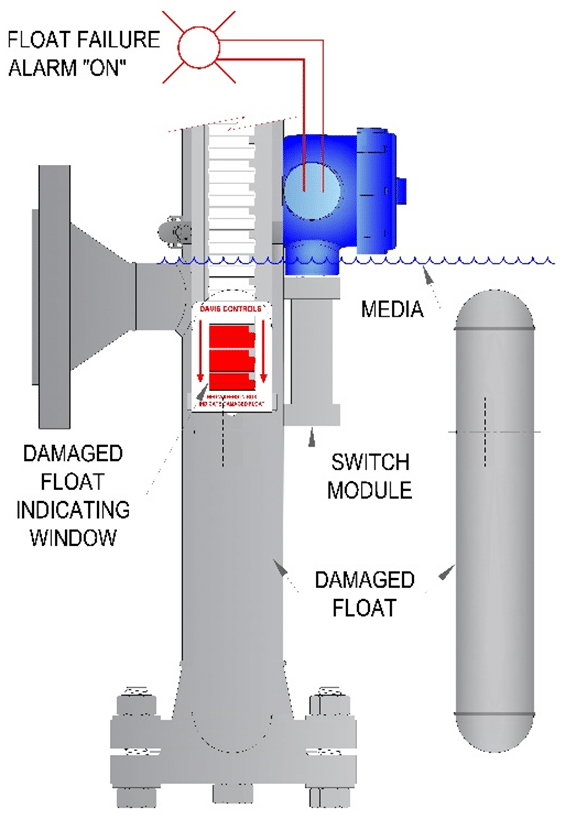

- Automatic float failure warning

- Display can be rotated through 360° irrespective of float position

- High pressure & temperature capability – up to 200 bar unvented up to 400°C

- Standard SG range 0.4 – 2.2

- Display unit protection IP67

Robust, shockproof and completely sealed for safety, Magnetic Level Gauges are particularly suited for dangerous or toxic fluids. Ideal for liquid interface applications with a powerful omni-directional magnet system contained within a non-pressurized float design.

How does it Work?

Applications

Our range of magnetic level gauges are suitable for a wide variety of processes and are the ideal solution across a several applications, including:

- Nuclear power industry

- Industries using dangerous and/or toxic liquids and gases

- Water and wastewater treatment

- Replacement for through-vision glass gauges that leak or are hard to read from a distance

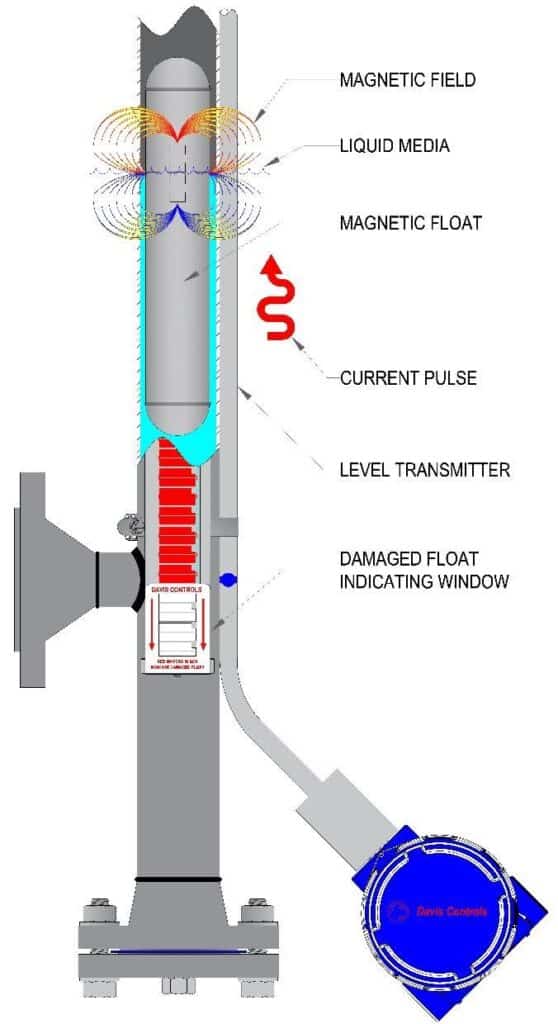

MAGNETOSTRICTIVE LIQUID LEVEL SENSORS

MAGNETOSTRICTIVE LIQUID LEVEL SENSORS consist of a stem, sensor head and a float that travels through the level chamber. The float contains a permanent magnet and the stem houses a wire waveguide. The level head generates electrical pulses which travel through the vertical wiring within the waveguide or sensor tube. These fixed pulses generate a magnetic field around the wire, which interacts with the float inside the process chamber.

THE WAVEGUIDE is constructed of a metal with ferromagnetic properties, making it possible to measure the float position. As a result, the molecules in the metal waveguide line up with magnetic fields. A magnetostrictive level transmitter uses two magnetic fields to align the molecules in different directions to create a detectable point on the wire waveguide. The waveguide is magnetized by an electrical pulse that passes across it, aligning the molecules in one direction. Molecules aligned in a different direction by the pulse’s contact with the float’s competing magnetic field cause a vibration to return to the sensor housing at a defined speed. This vibration is known as a strain pulse.

By measuring the time delay between the initial electrical pulse and resulting strain pulse, the distance to the float can be determined with a high degree of accuracy.

Features

- Explosion Proof – Class I Division 1 & 2 Groups C & D, Class I Zone 1, Class I Zone 2

- Highly accurate and repeatable readings

- 4-20 mA, RS-486 (Modbus RTU) output

- Rugged and reliable, lengths up to 12.74′ (3.9 m)

- Reverse polarity protection

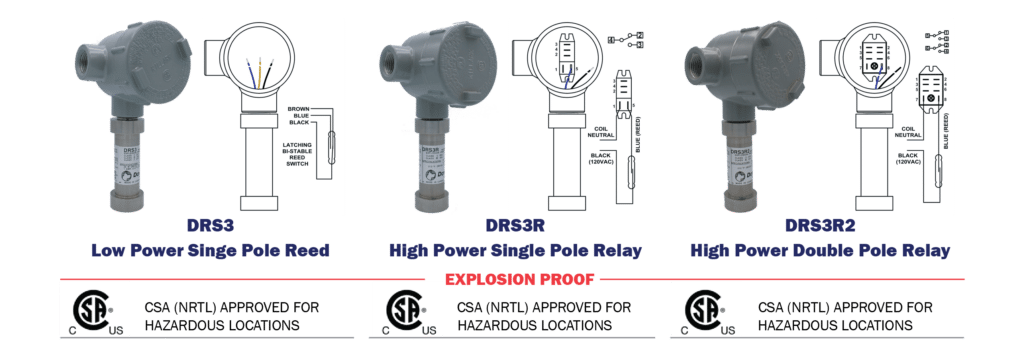

Explosion Proof Magnetic Level Gauge Switches