POSITIVE DISPLACEMENT METERS

High Quality Products Including Spur Gear, Helical Gear (or “screw-type”), and Rotary Piston PD Flow Meters. Positive Displacement (PD) flow meters are volumetric flow measurement instruments ideal for low flow rates, highly viscous fluids, and the measurement of flows involving starts and stops or pulsing. Positive displacement flow meters are similar in design to the gear pump. The principle of operation is reversed, however; instead of the gears driving the fluid, the fluid drives the gears. A non-intrusive hall-effect sensor detects the movement of the gear and as each gear tooth passes the sensor, a square wave pulse is produced, and a discrete volume of liquid is measured. The resulting pulse train is proportional to the actual flow rate and provides a highly accurate representation of the fluid flow.

SPUR GEAR

In Spur gear positive displacement flow meters, fluid travels around two round gears and is pushed through the meter’s internal chamber from the inlet to the outlet. The discrete volume of liquid trapped between each gear tooth is measured, as opposed to the Oval gear meter where a much larger volume between gears is swept through the chamber.

The SLG Compact Positive Displacement Spur Gear Meter is designed for measuring paints & coatings such as are found in the automotive industry. These stainless steel meters feature small, light bodies, perfect for installation on robotic arms and in other tight areas. Flow meter construction incorporates virtually no “dead space,” which allows for extremely efficient flush cycles and worry-free colour changes.

HELICAL GEAR

Possibly the most accurate PD meter in which two intersecting cylindrical bores are fitted with two interlocking helical screw-shaped gears. Because gear orientation is in line with flow, as the fluid passes through, the gears rotate with very little pressure drop. These flow meters are highly accurate over wide flow ranges and are compatible with very high-viscosity fluids.

SRZ-TC Helical positive displacement flow meter with tungsten carbide sleeve bushing was designed for measuring high viscosity, abrasive, and filled fluids as well as lubricating and non-lubricating fluids. Temperature fluctuations and the resulting change in viscosity of the fluid only marginally affect the measuring accuracy of these helical gear flow meters.

ROTARY PISTON

In this design, a rotary piston oscillates in the circular internal chamber displacing a fixed amount of fluid with each rotation. This style accommodates ultra low flows and high flows, as well as high pressures.

VFF Rotary Piston PD Flow Meter is ideal for use in applications with very low flow rates and high pressures, such as offshore chemical injection applications.

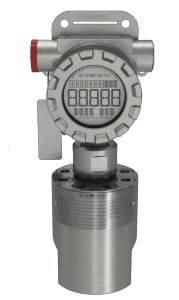

JV-BB POSITIVE DISPLACEMENT FLOW METERS

With ±0.5% accuracy over the full range of the meter, higher resolution, and higher pressure ratings while maintaining price, proven quality, and delivery. Designed for lubricating and non-abrasive fluids, such as oil, fuel, polyurethane, brake fluid, and other non-abrasive, low- to mid-viscosity lubricating fluids.

These high-performance flow meters have tighter machining tolerances, higher resolution, higher pressure rating, and improved accuracy over their predecessor the JV-KG meter and as a result, reduce operational costs.

This meter maintains high accuracy and repeatability, despite changing viscosity conditions, with up to ±0.25% accuracy with select sensors. Applications well suited to the JV-BB meters include chemical injection & dosing systems, fuel measurement, test stands, hydraulic positioning systems, and coolant & lubrication monitoring.

- Measuring Accuracy: ±0.5% over full range with 30cP fluid, ±0.25% optional with select sensors

- Six Flow Ranges: 0.005 – 120 gallons per minute | 7.2-172,800 gallons per day

- Pressure Rating: Up to 6,000 psi

- Calibration: 7-point logarithmic calibration

- Output Options: Wide variety of options available.

TURBINE FLOW METERS

Axial turbine flow meters are designed with wear resistant internal components to provide trouble-free operation and a long service life. Fluid entering the flow meter is first conditioned by the inlet flow straightener which reduces turbulence in the fluid. The moving fluid causes the rotor to spin at a speed that is proportional to its flow rate. As the turbine blades on the rotor pass through the magnetic field of the pickup, an electronic pulse is generated.

This pulse train signal can then be used to monitor the fluid’s actual flow rate or the total amount of fluid that has passed through the flow meter. The number of electronic pulses generated by the meter, per unit volume, is known as its K-Factor. Each flow meter is calibrated to find its unique K-Factor, which is supplied with the flow meter when purchased.

- Simple, durable design

- Easy installation and maintenance

- Reliable operation under a wide range of temperatures and pressures

- Turndown ratio is up to 35:1

- Good level of accuracy at an economic price

- Wide variety of process connections

- Low pressure drop

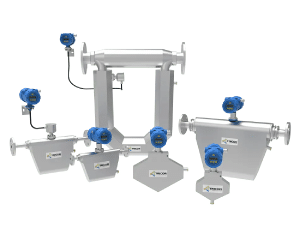

CORIOLIS MASS FLOW METERS

The TCM “CLASSIC” series of Coriolis Mass Flow Meters meets general industrial requirements with out-of-the-box ease of use.

- TCE 8000 transmitters: Easy-to-use interface

- Economically priced: 5-point calibration with excellent repeatability

- Optional custom-calibrated meters: With high performance specifications

- Accuracy suitable for most applications: ±0.1% of flow rate

- Net oil calculation built into software: Optional enhancement for oilfield allocation & verification

- Three pressure ratings: 6,000 psi, 10,000 psi, and 15,200 psi (414, 690, 1050 bar)

- Material choices based on use: 316L stainless steel for chemical injection, Sandvik Alloy HP 160 for hydrogen fuel

- Global OIML certification for Hydrogen: Allows custody transfer of Hydrogen in fueling operations

- Certified for Class I, Division 1 locations: Can be used in any safety classified area

VARIABLE AREA FLOW METERS

Variable Area flow meters, often referred to as “rotameters,” measure flow rate of a liquid or gas by relating the linear displacement of an internal “float” or sharp-edged orifice plate (Lake) to a corresponding flow rate. As the flow rate increases, the orifice area that the flow moves through also increases – thus, the term “Variable Area.” Variable Area meters either allow flow through a peripheral orifice formed between a tapered wall and a float as in the traditional rotameter, or an annular orifice and an internal tapered metering pin in the Lake Monitor. The attributes of the Lake Variable Area flow meter are a linear relationship between flow rate, pressure differential and piston displacement.

Flow rate is read on Variable Area meters by aligning the position of the piston/float to an adjacent calibrated scale.

- Relative low cost and ease of installation

- Robust and easy to maintain

- No need for auxiliary power

- Works with both liquids and gases

The LAKE Basic Inline Variable Area Flow Meter is ideal for monitoring pump performance and oil or water flows through hydraulic circuits and cooling systems. Often referred to as “rotameters,” Lake’s Basic meters are a low cost alternative to other flow meter types and are available in numerous materials of construction, including aluminum, brass and stainless steel to meet system and media requirements. The superior design not only makes this flow meter weather-proof for outdoor environments and wash-downs but also reliable, offering maintenance-free performance.

The Bi-Directional Variable Area Flow Meter is a high performing oil and water meter available in aluminum, brass, or stainless steel to meet system requirements. It measures bi-directional flow of oils and water, such as in test kits and mobile hydraulic systems. The high pressure operation, multiple ports available, and unrestricted mounting make this flow meter versatile, customizable, and easy to install. The all metal pressure vessels provide a safe and reliable, performance.

Pneumatic Flow Meters are ideal for monitoring air compressor outputs, pneumatic tool air consumption, and industrial gas flows. The rugged and reliable design includes all metal pressure vessels, allowing safe installation in industrial systems and industries. Enjoy the unrestricted mounting capabilities and easy installation with multiple ports available.

WTA SERIES HYDRAULIC ANALYZER

The WTA Series Hydraulic Analyzer is a simple compact design that allows for simultaneous measurement of flow, pressure and temperature on Mobile Industrial & Agricultural equipment. Its painted high-quality steel case enables the WTA Hydraulic Analyzer to withstand the most rigorous of use in the field. The WTA can be connected “Inline” between the pump and valve for convenient machine testing in all environments.

LAKE FLOWSTAT ES PADDLE WHEEL FLOW METER

Ideal for economically monitoring various fluids in applications such as chillers/cooling circuits, HVAC, batching and industrial process control applications.

- Measuring Accuracy: ±2.0% of full scale

- Flow Ranges: 0.5-15 GPM (2-60 LPM)

- Pressure Rating: up to 150 PSI

- Temperature Rating: 20-150°F

PROSCAN TURBIDITY SENSOR

Ideal for detection of material transitions, monitoring turbidity and measuring product concentration, such as in dairy processing, juice processing, and brewing operations.

Utilizing advanced optical and microprocessor technology, ProScan produces a linearized 4-20 mA output that can be tailored to a wide range of applications. The sensor attaches directly to the process line and allows real-time, in-line analysis of fluid streams. The sapphire lens and 316 stainless steel body will withstand the high temperatures, rapid temperature fluctuations and chemical agents typical in food processes.

- Four Sensor Sizes:1-1/2″, 2″, 2-1/2″, and 3″

- Stainless Steel Housing: NEMA 6 / IP67 enclosure

- Versatile: Multiple display modes

- Process Control: Monitors dispense operation